LST 1096 Service & History

The first LST’s were 280 feet long and 45.4 feet wide. Later they were built to be 328 feet long and with a 50 foot beam, like the 1096.

The first LST’s were 280 feet long and 45.4 feet wide. Later they were built to be 328 feet long and with a 50 foot beam, like the 1096.

The ship had a flat bottom, a sloping keel, 7.5 foot draft forward, 14 foot draft aft, 16 foot freeboard, and a tank deck 230’x30’x12’. The hull plating was 3/8”, and to be exact, one inch under the hull.

There were only five variations to the original design and each ship had about 30,000 parts. Designed to ground evenly, LST’s have twin rudders and screws, 40 feet apart. The 1096 could carry 1,060 tons of fuel, (265,000 gallons), 600 tons of cargo on the tank deck, and another 300 tons on the main deck. This resulted in 33.3 tons per inch of draft. She could distill 4,000 gallons of water per day. Each main engine burned (at 744 RPM) 7.5 gallons of fuel per mile, 82.5 gallons per hour, 1983 gallons per day. She also could hold 5,950 gallons of lubricating oil 483,297 gallons of ballast salt water, and 120,260 gallons of fresh water. Oh, and each anchor weighed in at 3,000 pounds, (Danford type). Usually the LST was fitted out with 6 crew officer staterooms, 12 crew-enlisted compartments (9 per compartment), 4 troop officer staterooms, and berths for 116 enlisted troops (92 bunks Starboard and 24 Port).

Most of the “figures” mentioned above were provided from the LST News, “UP SCOPE”, (a publication of the Great Lakes Naval Memorial and Museum, P.O. Box 1692, Muskegon, Michigan).

BY: MELVIN HARLEY JASMIN

RET. Military

Lieutenant James W Knox, U.S.N.R. (Retired), researched much of the following information (##)

What is an LST? How did it come about? Why was it so important during the Second World War and, even in Korea?

After the disastrous defeat at the Dardanelles, the principal amphibious experiment in World War 1, a small group of U.S. Marine and Naval Officers dissected this campaign and concluded that future amphibious assaults were feasible if certain conditions were met. These conditions included requirements for a specially trained landing force, an integrated naval and landing force command, adequate ship-to-shore communications, adequate air cover, suitable amphibious transports, landing craft and amphibious vehicles, and many contributory techniques such as combat loading of amphibious shipping and workable shore-based control of naval gunfire, close support aircraft as a result of these studies, and the fleet exercises which tested their findings. The United States entered World War II with a well-developed amphibious theory that was adopted by all the major allied powers. The failure of Germany to develop an adequate amphibious doctrine was a major contributory cause of Hitler's ultimate defeat. The LST became the work- horse of the allied powers. They were unique in that they had a beaching capability. Through agreement of American and British Officers, the design was soon completed and production ready to start.

Although President Franklin D Roosevelt had declared a limited emergency after the outbreak of War in Europe in 1939 to beef-up the armed forces of the United States, everything changed rapidly after the bombing of Pearl Harbor by the Japanese on December 7, 1941.

Admiral SS Robinson, Chief Bureau of Ships – United States Navy, summoned JD Berg, Chairman and VB Edwards, President of the DRAVO Corporation (Pittsburgh, Pennsylvania), to Washington D.C. where he outlined the plans to build an amphibious force for the Navy. The first formal defense order to DRAVO was for the construction of six patrol craft (PC-sub-chasers). These were warships 165 feet long with sleek lines of a yacht for speed and maneuverability. The construction of sub-chasers with their molded hulls presented complex problems in yard assembly and handling operations than the customary flat bottom barges. Contoured cradles and other adaptations that allowed full use of DRAVO assembly line and standardization techniques solved these problems. When PC 490 was launched, history was made.

outlined the plans to build an amphibious force for the Navy. The first formal defense order to DRAVO was for the construction of six patrol craft (PC-sub-chasers). These were warships 165 feet long with sleek lines of a yacht for speed and maneuverability. The construction of sub-chasers with their molded hulls presented complex problems in yard assembly and handling operations than the customary flat bottom barges. Contoured cradles and other adaptations that allowed full use of DRAVO assembly line and standardization techniques solved these problems. When PC 490 was launched, history was made.

It was the first war ship built by DRAVO, the first combat Navy vessel of appreciable size ever to come off an assembly line, and the first sea going vessel launched at an inland river shipyard since the War of 1812. Admiral Robinson stated "If these vessels are produced in the time required, the war will be one year shorter than it will be if we fail".

The Navy became very interested in DRAVO' S rapid production methods. There were three outstanding innovations. One was the use of serrated channels as stiffeners for hull and bulkhead plating. Another was the jigging and manipulating of large pre-assemblies to achieve maximum production rates and optimum quality of welding. This made possible fabrication of large quantities of hull sections, bulkheads, deckhouse and other components, and stored them until needed. The third innovation was a method of moving hulls progressively from the keel-laying position through a series of erection berths to final position for launching. The device that made this possible was a transfer buggy developed by DRAVO in 1934. This four-wheeled carriage with built-in jack capable of lifting 300 tons. A group of buggies on tracks could lift an entire hull clear of its erection berth, move it forward, and lower it on the next berth. This permitted segregation of stored materials and specific operations at each berth for orderly and efficient accomplishments of the work.

DRAVO made these fundamental contributions to the ship building art to many other shipyards in the production of the Landing Ship Tank (LST). DRAVO was asked by the Navy to serve as the "lead yard". The LST, first known as the Atlantic Tank Landing Craft (ATLC), was to be 326 feet long with a beam of 50 feet, and was expected to cost $1,500,000 each.

The unique features that distinguished an LST from any previous craft were its bow doors, ramp arrangement, ballast compartment, and pumps. These made it possible for the Captain to decrease the draft forward of mid-ships, beach the vessel, open the bow doors, lower the ramp, promptly discharge men, vehicles and materials, and then back off with the aid of anchors and winches. This was a ship designed for invasion for landing on an unfriendly beachhead where the maneuver could not be rehearsed and where it must not fail.

This critical program of shipbuilding required the combined services of a great many people and the cooperation of a large number of engineering companies, manufacturing plants and financial institutions; all pooled their resources to a common goal. Behind DRAVO as lead yard during the LST program, four other inland shipyards were outfitted with special handling equipment to use the DRAVO pre-assembly and hull-moving techniques to speed up production. They were American Bridge Division, U.S. Steel Corporation, Abridge, Pennsylvania; Chicago Bridge & Iron Company, Senaca, Illinois; Jeffersonville Boat and Machine Company, Jeffersonville, Indiana; Missouri Valley Bridge & Iron Company, Evansville, Indiana; what a record. These yards together with DRAVO turned out 724 LSTs – 68% of the Navy's entire fleet of 1058 LST's. DRAVO's experienced methods and special equipment were made available to other yards regardless of the effect such sharing might have in competitive postwar markets.

The greatly enlarged work forces at the various shipyards brought people from all walks of life, many of whom had no previous experience in industry. Most came because of a sincere desire to be of service to their country and willingly accepted any job assignment that would assist the war effort. Experienced workers trained inexperienced helpers and the shipbuilding companies established schools for formal training in more than a dozen special skills. Thousands of men and women enrolled in courses to prepare themselves for welding, pipe fitting, electrical work, ship-fitting, rigging, pipe insulating, rate checking, job methods, time keeping, blue print reading, foremanship, and many other skills.

The greatly enlarged work forces at the various shipyards brought people from all walks of life, many of whom had no previous experience in industry. Most came because of a sincere desire to be of service to their country and willingly accepted any job assignment that would assist the war effort. Experienced workers trained inexperienced helpers and the shipbuilding companies established schools for formal training in more than a dozen special skills. Thousands of men and women enrolled in courses to prepare themselves for welding, pipe fitting, electrical work, ship-fitting, rigging, pipe insulating, rate checking, job methods, time keeping, blue print reading, foremanship, and many other skills.

The Secretary of the Navy, James FORRESTAL, visited all of the shipyards bringing a message from President Roosevelt urging increased production. The production rates increased substantially. For example, the Neville Island yard of Dravo Corporation produced 145 LSTs with an average production rate of one every 6.1 days. During April and May of 1944, Neville Island's "hot ship" period, the yards launched one LST every 3.5 days in preparation for "D" Day.

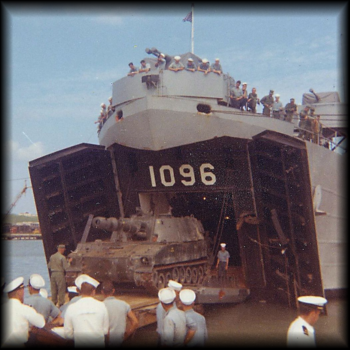

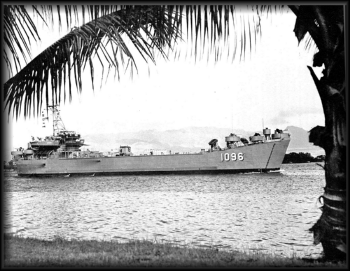

Below is the LST 1096. She was built by the Jeffersonville Boat & Bridge Company in 1945 and commissioned in February of that year. Five skippers held command of the ship up until its being decommissioned in late 1946. Prior to her going out of service she was involved in several assaults on the beaches of Okinawa. During her decommissioned days the 1096 became part of the vast mothballed fleet at Tongue Point, near Astoria, Oregon.

On October 3 1950, the LST 1096 was re-commissioned because of the "Police Action" in Korea. After a few months of reconditioning at Puget Sound, she sailed for Japan in February 1951. From February to November, the 1096 moved between Japan and Korea in support of the United Nations Forces. For the most part the ship was used to transport prisoners of war. In November 1951 the ship returned to the U.S. and entered the yards She remained there until early 1952 when she was again, summoned by WESTPAC. She served with the UN Forces in Korea and Japan until September 1953 and was again actively engaged in prisoner exchange called "Little Switch", and carried supplies to INCHON, among other locations.

LST 1096 returned to the United States in October 1953 and reported to the ship yards at Long Beach, CA, where she was re-fitted until March 1954. She then returned to Korea and Okinawa where she was involved in many landing exercises. She then proceeded to HAIPHONG French Indo China and operation "Passageway to Freedom".

The ship returned to CONUS in February 1955 and in July of that year was christened USS St CLAIR County. Her name was taken from the name of Counties in Alabama, Missouri, Illinois and Michigan. During the latter months of 1955 the St CLAIR prepared to join up with WESTPAC for the 4th time. On the 10th of February, 1956 she joined Task Force 90 in the Far East and took part in an amphibious landing exercise at IWO JIMA (These landings marked the 11th anniversary of the original IWO JIMA landings during World War II.

Between February 1956 and September 1956 the St CLAIR took part in three amphibious exercises and visited YOKOSUKA, KOBE, MOFI and SASABO Japan; Naha and BUCKNER BAY, Okinawa; Hong Kong, SUBIC Bay and Korea and IWO JIMA, again. She then returned to Long Beach, CA and participated in landing exercises off Camp PENDLETON, Marine Corps Base.

All through 1957-to 1965, the LST 1096 was on active duty, involved in many training exercises and hauling equipment and materials and troops over large areas of the World. In January 1966 she was again called into a combat zone, in Vietnam!….In her almost nine months in the 7th fleet in that area she steamed over 22,000 miles, made twenty beach landings, hauled over 15,000 tons of vital cargo and logged over 1,000 miles on Vietnamese rivers. Upon her departure from Vietnam the St CLAIR County was commended by RADM WESCHLER for her achievements in the VIET NAM struggle and awarded the Vietnam Service Medal and the Vietnam Campaign Medal.

Some "Humorous" things did happen aboard the LST 1096;such as in April 1960 when the ship was involved in "BLUESTAR" Exercises off China, the ship was part of the background scene for the movie "The Wonderful World of Susie Wong". Then in December of that same year, the St CLAIR moved to the center stage as she played one of the leads in the movie, "All hands on Deck". (A variety of temporary changes were made to the ship to get her ready for Pat Boone, Barbara Rush and Buddy HACKETT and Company)

Wonderful World of Susie Wong". Then in December of that same year, the St CLAIR moved to the center stage as she played one of the leads in the movie, "All hands on Deck". (A variety of temporary changes were made to the ship to get her ready for Pat Boone, Barbara Rush and Buddy HACKETT and Company)

An incident happened while en-route to YOKOSUKA from exercises off the Honshu coast with army personnel and equipment aboard. In late 1952 the LST 1096 and several others were racing at the top speed of 12 knots down the Pacific side of BOSO Peninsula to come around and into the SAGAM Sea, which would lead us to our Naval base and away from a very bad typhoon bearing toward us from out of the Pacific. (We later learned it veered away and struck the Yap Islands). The winds & high seas slammed the 1096 up and down so hard that several pieces of army equipment were lost overboard from the main deck. In this loss was a particular Army jeep and its trailer. The humorous part, (to the Navy personnel anyway), was that several army people had pooled their money and purchased dozens of cartons of cigarettes from our small store aboard ship and had placed them in the missing trailer. They were going to make a small fortune selling them on the street in either Japan or Korea!

For those serious minded people who will be looking for further information about the LST, or the particular one they served on, contact with the UNITED STATES L.S.T. ASSOCIATION is highly recommended. Write to them at P.O. Box 167438 Oregon, Ohio 43616-7438. You can phone them at 1-800-228-5870 and FAX them at 1-419-693-1265…Or you can punch in their web site: www.uslst.org

My service in the Navy on the LST 1096 lasted only eight months but it was a learning experience I'll never forget. I was only 17-18 years old. I had never been at sea and here I was going off to fight a war I knew nothing about. I was able to visit, HAWAII and the famous beaches and Pearl Harbor, and the great Bronze BUDDA at KAMAKURA in Japan and Seoul, Korea. I really did not see war face to face. Mine was from miles. The enemy to me, were ants through field glasses. It only came home to me when I saw the wounded coming in to INCHON and other places to be lifted out to ships like the Hospital ship, JUTLANDA, and seeing them in the hospitals later in Hawaii and Oakland, CA., where I eventually landed.

Please Feel Free To Contact me through mel@houseofjasmin.com or Call 503-861-2030. *(Images courtesy of NavSource)